Home >> Technology >> Gear Technologies

Gear Technologies safely and flexibly manipulates power.

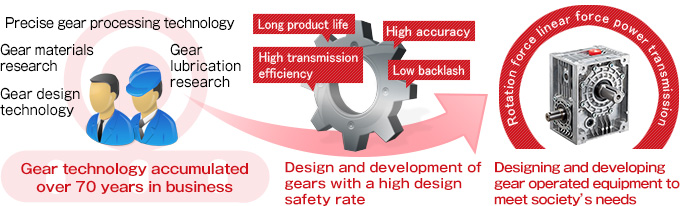

The gear technologies that Makishinko has obtained over a half century of history have been highly refined by Makishinko's own solid organizational strength and structure. Within this organization, the knowledge, skills, experience and passion of each of Makishinko staff member are organically concentrated on clear business goals in order to provide equipment that work as solutions to confidently address the needs of the modern era.

Makishinko machinery continuing the advance towards the next generation

- Worm Speed Reducer

Worm Speed Reducer have long been a top seller for Makishinko. Makishinko is developing next-generation technologies one after another to answer customer needs. This includes establishing a new series with a 10% or more improvement of transmission efficiency over previous Worm Speed Reducer through a clever combination of proprietary gear technologies, as well as using special lubricants for low noise operation or other special needs and the joint development of gear materials.

- Jacks

In addition to the technologies accumulated for Worm Speed Reducer, jacks are available for all stroke ranges to meet customer demands. The optimal screw shaft for the application can be selected, either a trapezoidal screw with a self-locking function or a ball screw that does not have holding force, but has a small backlash. This series uses a tapered roller bearing that is durable against thrust and has an optimal bearing structure.

- Bevel gears

Bevel gears are a power splitting gearbox with orthogonal input and output shafts. The two types of bevel gears are spiral bevel gears and straight bevel gears. Gears with deliberately considered designs and superb finishing accuracy are attached precisely, producing low operating noise and smooth high-speed rotation. This makes it possible to achieve high capacity in a compact lightweight design. The shaft is made of carbon steel or other special steel as a part of a design to provide durability versus bending force.

Composite device products that work as storage solutions

- Vertical rotary automated storage (Rotary stocker)

The storage shelves are utilized for storing mechanical components and equipment. By interlocking operation with a computer, inventory storage and retrieval and inventory management can be plant automated. The storage shelves are rotated to reduce the space required for the storage and retrieval of objects. Makishinko can also respond to specialized specifications such as explosion-proof and refrigerated units. By applying gear technologies, this product can operate smoothly even when storing overweight loads.

- Variable height vertical automated storage (Shuttle)

Vertical automated storage technology is the product of gear and control technologies. The storage height is detected automatically, offering high density storage with dead space eliminated. The system also contributes to space-saving for the customer by responding flexibly according to the stipulated storage location and purpose of the customer in response to the maximum weight per tray and storage height.